This article explores the phenomenon of pad tapering and what causes this on a multi-piston brake caliper

Unfortunately, you will always see some degree of pad tapering. It is common to see a few millimetres of taper, and this is totally normal. Furthermore, in track-based driving situations, you may see slightly more tapered wear. Pad tapering is completely inescapable, but there are things that can be done to limit it.

Pad tapering on multi-piston calipers can be caused by many issues, including but not limited to:

- Incorrect caliper installation

- Seized pistons

- Uneven differential in pressure between the leading and trailing edge of the caliper

How are EBC calipers different and what do they do to eliminate excessive pad taper?

Staggered Pistons

Multi-piston brake calipers in the past frequently utilised the same-sized pistons in both leading and trailing positions, especially in 4-piston calipers. Multi-sized (staggered) pistons tended to only be implemented into 6-piston calipers (and above).

With calipers that are fitted with the same-sized leading and trailing pistons, you often will notice pad tapering, and this is further amplified when the vehicle is used for track days due to the pressure distribution between the leading and trailing edge of the caliper.

On all EBC Apollo series calipers, staggered pistons are incorporated which allow us to fine-tune the differential of pressure between the leading and trailing edge of the caliper. When a smaller diameter piston is used on the leading edge (the side where the rotating disc/rotor passes first), this ensures that the brake force is evenly distributed across the pad and thus combats pad tapering.

An example of this is our Apollo-4 (100 series) brake caliper, where the leading pistons are 38.1mm in diameter and the trailing piston sizes are 41.2mm in diameter – allowing us to shift the distribution of pressure more evenly. The reasoning behind the use of smaller-sized pistons at the leading edge and larger sized pistons at the trailing edge is that less pressure is applied to the smaller pistons (leading) and more pressure can be delivered by the larger pistons (trailing), forcing the pistons to clamp the pad and thus the disc/rotor in such a way that will even out taper wear on the pads.

Unfortunately, it is near impossible to completely eradicate taper wear completely.

Sticking/Seized Pistons – How do We Combat This?

All EBC Apollo brake caliper bodies are initially hard-anodised for excellent corrosion resistance and extended caliper longevity. We then fit our lightweight hard-anodised aluminium pistons with serrated piston noses that reduce heat transfer into the braking hydraulics and finally top this off with high-temperature fluid seals coupled with full boot-type dust seals, to give maximum protection against road grime and debris – all of this leads to a system that is well protected from the issue of seized pistons. However, it is key that on any braking system, preventative maintenance is always carried out, especially if the system is being used in a harsh environment or on track days and such like.

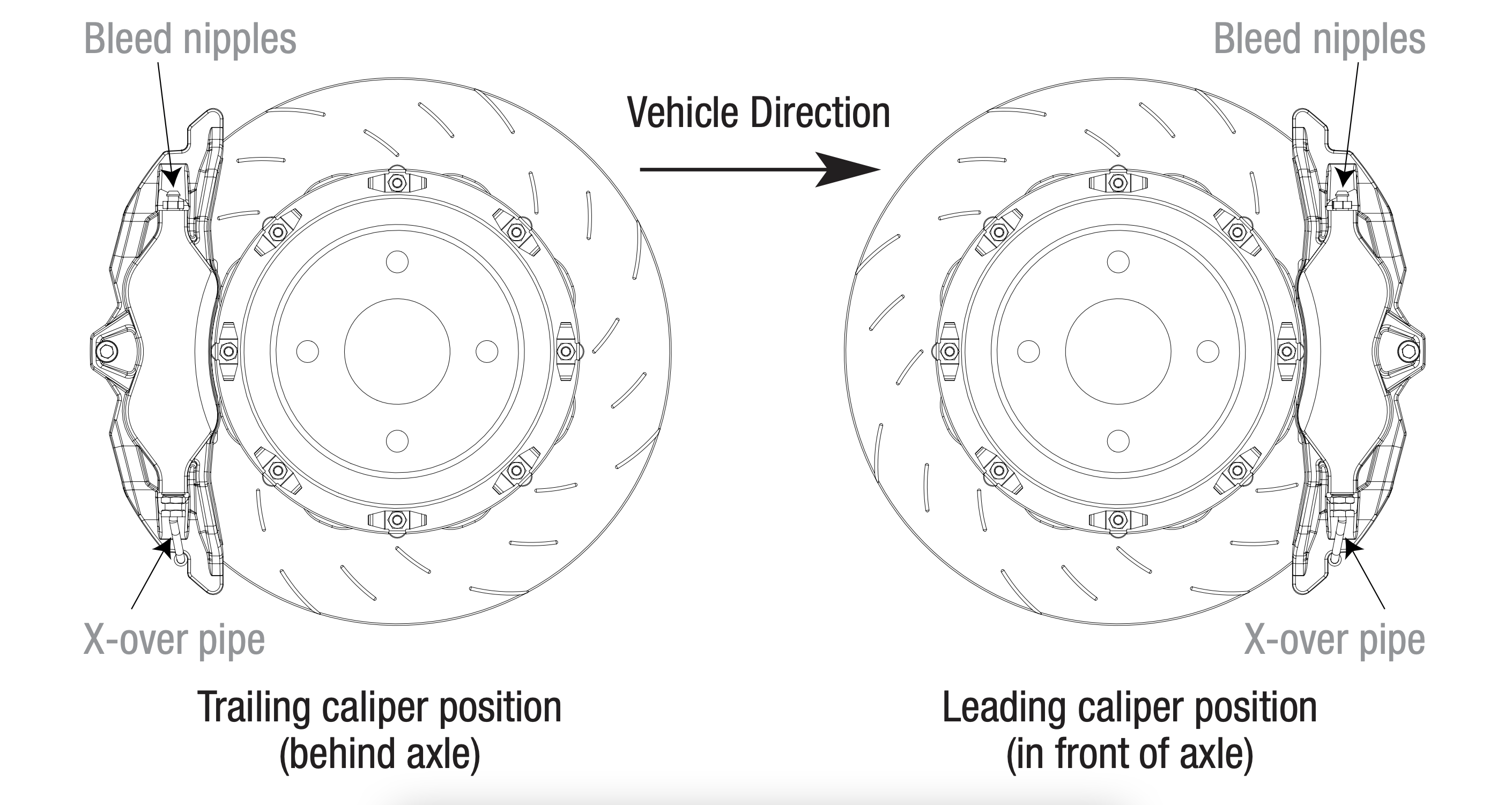

Leading vs Trailing Calipers (Caliper Handing and the Correct Fitment)

When fitting new Apollo series calipers, always check the hand of the caliper by observing the casting number machined into the piston face. Whether the caliper is right/left handed will be denoted at the end of the casting number, for example “4101R/6101R”. (The left/right hand side of the vehicle is referenced to the driver sitting in the driver’s seat). The disc/rotor must also always pass the smaller diameter (leading) piston first.

The caliper orientation must always be such that the bleed nipples point up with the fluid cross-over pipe at the bottom. Calipers not installed close to the vertical may present a problem during bleeding.

EBC Apollo 4- and 6-Pot Calipers – Key Features

- High-temperature fluid seals coupled with full boot-type dust seals to give maximum protection against road grime and debris

- Lightweight hard-anodised aluminium pistons with serrated piston noses that reduce heat transfer into the braking hydraulics

- Staggered piston sizes to eliminate pad taper

- FEA-optimised geometry ensuring maximum body stiffness for minimum caliper weight

- Hard-anodised caliper body for excellent corrosion resistance and extended caliper longevity

- Every single brake caliper is pressure tested to 2500psi

- Full stainless-steel hardware and fittings, providing durability and longevity

- Uses standard pad shapes, giving choice when selecting brake pads

EBC Apollo series brake calipers are cast in UK, machined in the UK, painted in the UK and then assembled in the UK – reinforcing the EBC philosophy of providing quality British-made braking products yet at affordable prices.

With so many calipers in this segment of the market being bought in from Far East, surely this is the ultimate testament to EBC’s devotion to quality. EBC are and will always be a true champion of Great British engineering.

Find out more about EBC Brakes’ upgraded calipers by clicking here.

Non-EBC Caliper Pad Taper

If you are not planning to change calipers to something with better engineering, you may get some benefits by using a pad with a one-ended chamfer on the friction material, which essentially moves the centre of effort and can help reduce or prevent taper.

EBC Brakes has introduced this for various applications to combat pad taper. For more information, please email raceinfo@ebcbrakes.com.